By John Dzelme, global chief operating officer, Seabrook Technology Group

The emergence of Industry 4.0 will have particular significance for the Irish economy – now is the time to prepare for the next great industrial revolution.

If you haven’t already heard of Industry 4.0, it won’t be long until it will be as normal a part of our language as the terms ‘wi-fi’ or ‘social media’.

Industry 4.0 is a term first coined in Germany, and is used to describe the next great industrial revolution. A revolution that will bring unprecedented transformations, fundamentally altering the way we live and work.

It has particular importance for Ireland because it has specific significance for medical device manufacturers and life science organisations.

At the moment, 18 of the 25 largest medtech companies in the world are based in Ireland. Annual exports are worth €8.5bn to the economy, making Ireland one of the leading exporters of these products in the world.

The sector is also a huge employer with 27,000 people working in medtech companies. If Ireland wants to continue to be a world leader in the area, organisations need to be ready for the Industry 4.0 revolution.

THE DIGITAL AGE

Industry 4.0 builds upon the third industrial revolution of automation. The first industrial revolution was the advent of steam, water and mechanical production, the second was electricity and mass production, finally the third being automation.

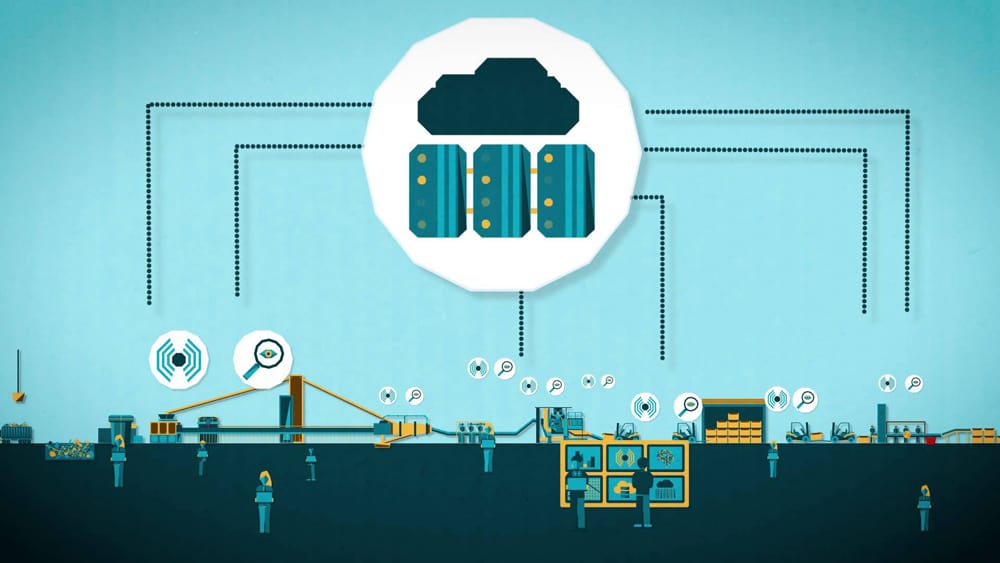

We are now on the brink of the fourth, ‘the digital age’, that will be characterised by a fusing of the physical and virtual worlds.

The new era will bring together the Internet of Things, advanced technologies in data analytics and artificial intelligence to the manufacturing industry in order to transform the way goods of all types, including medical devices are produced.

Terms like ‘digital factory’ and ‘smart factory’ are synonymous with Industry 4.0. In the digital factory, advanced technologies will enable the creation of a ‘virtual twin’ of a product.

It means that products will be improved, redesigned and vigorously tested in the virtual world before a single part is ever created in real life.

The technologies and software required for Industry 4.0 might be seen as advanced now, but they will be standard in a few short years’ time

This results in faster time to market for new products, and better quality for consumers; not to mention the fact that these technologies will completely eradicate the need for paper-based files and storage.

This capability will enable greater innovation and faster speed to market than we have seen to date with medical devices.

In Industry 4.0, products will not only be of an enhanced quality, but these technologies will also enforce compliance with health industry regulations, before the product ever leaves the shop floor.

DEEP IMPACT

Management consultant Roland Berger recently conducted an EU study on the effects of full digitisation of industrial production. He concluded that there would be an increase of €250m in the EU’s GDP in the medium-term alone.

The impact that Industry 4.0 will have on wages and quality of life shouldn’t be underestimated. It’s concerning, however, that European companies are still lagging far behind their competitors in America and Asia, and there is a tendency to put off making the necessary changes now that will allow them to remain competitive in the future.

The technologies and software required for Industry 4.0 might be seen as advanced now, but they will be standard in a few short years’ time.

A lot about Industry 4.0 remains unclear, but what is clear is that companies that are embracing the technological transformations now will be the innovation leaders of the future.

About the blogger

About the blogger

John Dzelme is global chief operating officer with manufacturing software specialists Seabrook Technology Group.

John leads global operations for the company and is an internationally recognised expert in (manufacturing execution systems (MES), lean manufacturing and manufacturing intelligence strategies.

He is committed to driving operational excellence through the use of technology, particularly in the life sciences sector.

John will speak at the Preparing for Industry 4.0 conference in Dublin on April 25th.